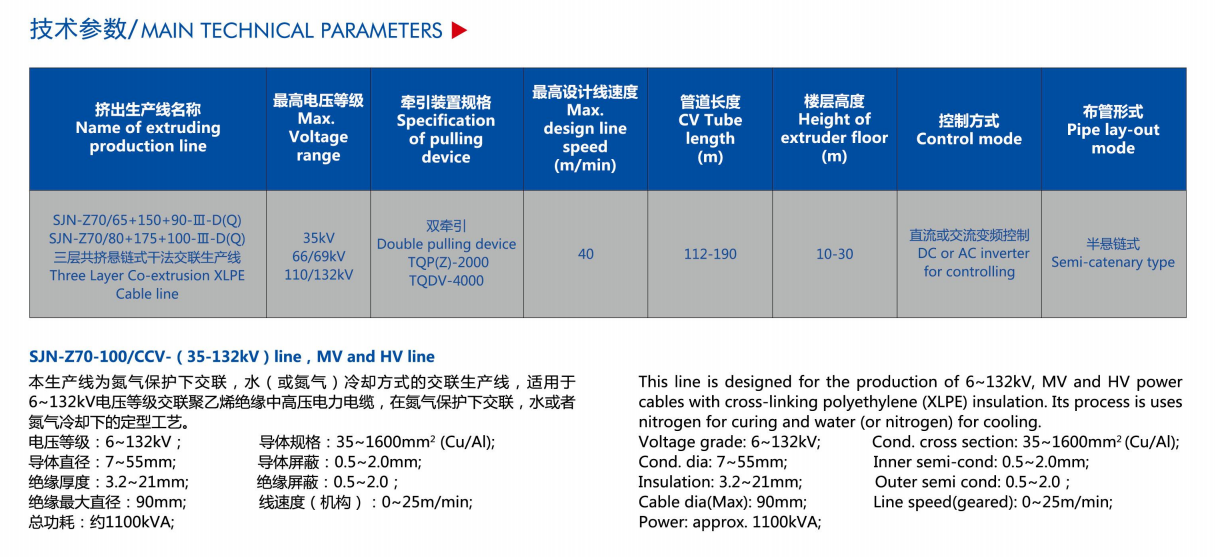

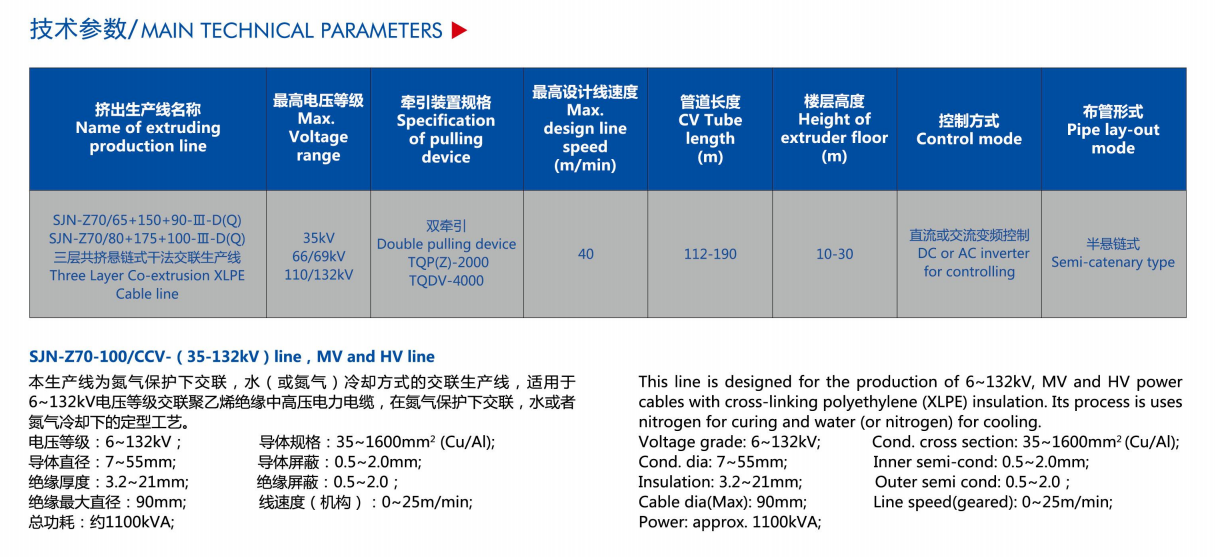

The 6-132kV Triple-layer CCV Line for XLPE Cables represents the pinnacle of high-voltage cable manufacturing technology, integrating decades of engineering expertise to deliver consistent cross-linking quality and industry-leading production efficiency. At its core lies the Continuous Vulcanization (CCV) process, a revolutionary approach that eliminates the limitations of batch curing by enabling uninterrupted production of XLPE-insulated cables across the 6-132kV voltage spectrum. This system strictly adheres to IEC 60840 and IEEE 404 standards, ensuring each cable meets rigorous electrical performance criteria, including dielectric strength ≥30 kV/mm and volume resistivity ≥1×101? Ω·cm.

| Availability: | |

|---|---|

| Quantity: | |

Its closed-loop temperature control system achieves ±1.5°C accuracy across 6-9 heating zones, while precision pressure regulation (±2% tolerance) within the curing tube eliminates common insulation defects like voids, impurities, and uneven cross-linking. Field data shows this technology reduces material waste by 25% compared to traditional steam-curing methods, translating to significant cost savings for high-volume production. Designed for versatility, it seamlessly accommodates submarine cables, urban power grid cables, and renewable energy interconnection cables, with production speeds reaching 30 m/min—30% faster than conventional CCV lines. The modular architecture allows easy integration into existing facilities, with customizable configurations for specific cable diameters and insulation thicknesses.

Cross-linking Method: The nitrogen-filled CCV tube creates an oxygen-free environment critical for XLPE vulcanization, with multi-zone heating (6-9 independently controlled zones) ensuring uniform temperature distribution. This design eliminates oxidation-related defects, achieving cross-linking degrees ≥75% across the entire cable length.

Temperature Control: PID-controlled ceramic heaters maintain precise 230-300°C curing temperatures, validated through real-time thermal imaging systems that monitor tube wall and cable surface temperatures simultaneously. Over-temperature protection triggers at 310°C to prevent material degradation.

Line Speed: Variable from 0.5-30 m/min via frequency conversion drive, with soft start/stop functionality to avoid thermal shock. Supports thin-wall insulation (0.5 mm) for low-voltage applications and thick-wall designs (19 mm) for 132kV high-voltage cables.

Extruder: Equipped with a φ90-φ150 mm single-screw extruder featuring a 20:1 L/D ratio and barrier-type screw design, optimizing melt homogenization and output stability. The extruder delivers 150-800 kg/h of XLPE compound, with a grooved feed section to handle high-viscosity materials efficiently.

Curing Tube: Constructed from 316L stainless steel for corrosion resistance, with an internal diameter of 200-400 mm (customizable) and seamless welding to prevent nitrogen leakage. The closed-loop nitrogen recovery system reduces consumption to ≤5 m³/h—40% lower than open-loop designs.

Cooling System: Double-stage water spray cooling with precision nozzles rapidly reduces cable temperature from 300°C to ≤50°C within 60 seconds, minimizing thermal stress and ensuring dimensional stability. The first stage uses recirculated water (60-70°C) for controlled cooling, while the second stage employs chilled water (15-20°C) for final temperature reduction.

PLC+HMI Interface: A 15-inch touchscreen provides real-time monitoring of insulation thickness (±3% accuracy via laser micrometers), line tension (50-5000 N range), and nitrogen pressure (0.2-0.6 MPa). Supports remote access via industrial Ethernet for process optimization.

Safety Features: Explosion-proof design (ATEX Zone 2 certification) for the curing tube area, automatic nitrogen leak detection with audible/visual alarms, and emergency shutdown within 0.5 seconds of critical parameter deviations.

Power Transmission

Manufactures 110-132kV XLPE cables for long-distance energy transmission networks, with low dielectric loss (≤0.002 at 50Hz) ensuring minimal energy waste. Complies with DNV GL requirements for offshore wind farm inter-array cables, including resistance to salt mist and UV exposure.

Enables production of segregated phase cables for urban substation connections, with precise insulation concentricity (±5% tolerance) to prevent partial discharge.

Industrial Infrastructure

Produces 6-35kV cables for mining and heavy industry, featuring high abrasion resistance (Taber test ≤5 mg loss after 1000 cycles) and flame retardancy (IEC 60332-3-22 Cat. C).

Supports armored cable production with integrated steel tape application, ensuring mechanical protection in harsh environments.

Submarine Cable Systems

Processes armored submarine cables (50-150 mm diameter) with water-blocking layers (longitudinal and radial), tested to IEC 60727 standards for water tightness under 10 bar pressure.

Accommodates lead or aluminum sheathing lines for additional corrosion protection in marine environments.

Renewable Energy

Manufactures cables for solar inverter connections and wind turbine interconnections, with UV resistance (ISO 4892-3:2016 3000-hour exposure) and -40°C low-temperature flexibility (IEC 60811-404 test).

Q: What voltage ranges can this CCV line handle?

A: It supports 6-132kV XLPE cables as standard, with customizable cooling segments and extrusion parameters to accommodate insulation thicknesses from 0.8 mm (6kV) to 12 mm (132kV).

Q: How does the nitrogen consumption compare to traditional systems?

A: The closed-loop nitrogen recovery system recycles 90% of used nitrogen, reducing consumption by 40% (≤5 m³/h) compared to open-loop systems that typically use 8-10 m³/h.

Q: Is it compatible with third-party compound suppliers?

A: Yes, it works seamlessly with all major XLPE brands (e.g., Dowlex?, ExxonMobil Enable?), with material-specific screw profiles available for optimized processing of different compound formulations.

Q: What certifications does this line hold?

A: It complies with CE (Machinery Directive 2006/42/EC), ISO 9001:2015 for quality management, and ISO 14001 for environmental sustainability, with low noise emission (≤85 dB(A)) and energy-efficient components.

Its closed-loop temperature control system achieves ±1.5°C accuracy across 6-9 heating zones, while precision pressure regulation (±2% tolerance) within the curing tube eliminates common insulation defects like voids, impurities, and uneven cross-linking. Field data shows this technology reduces material waste by 25% compared to traditional steam-curing methods, translating to significant cost savings for high-volume production. Designed for versatility, it seamlessly accommodates submarine cables, urban power grid cables, and renewable energy interconnection cables, with production speeds reaching 30 m/min—30% faster than conventional CCV lines. The modular architecture allows easy integration into existing facilities, with customizable configurations for specific cable diameters and insulation thicknesses.

Cross-linking Method: The nitrogen-filled CCV tube creates an oxygen-free environment critical for XLPE vulcanization, with multi-zone heating (6-9 independently controlled zones) ensuring uniform temperature distribution. This design eliminates oxidation-related defects, achieving cross-linking degrees ≥75% across the entire cable length.

Temperature Control: PID-controlled ceramic heaters maintain precise 230-300°C curing temperatures, validated through real-time thermal imaging systems that monitor tube wall and cable surface temperatures simultaneously. Over-temperature protection triggers at 310°C to prevent material degradation.

Line Speed: Variable from 0.5-30 m/min via frequency conversion drive, with soft start/stop functionality to avoid thermal shock. Supports thin-wall insulation (0.5 mm) for low-voltage applications and thick-wall designs (19 mm) for 132kV high-voltage cables.

Extruder: Equipped with a φ90-φ150 mm single-screw extruder featuring a 20:1 L/D ratio and barrier-type screw design, optimizing melt homogenization and output stability. The extruder delivers 150-800 kg/h of XLPE compound, with a grooved feed section to handle high-viscosity materials efficiently.

Curing Tube: Constructed from 316L stainless steel for corrosion resistance, with an internal diameter of 200-400 mm (customizable) and seamless welding to prevent nitrogen leakage. The closed-loop nitrogen recovery system reduces consumption to ≤5 m³/h—40% lower than open-loop designs.

Cooling System: Double-stage water spray cooling with precision nozzles rapidly reduces cable temperature from 300°C to ≤50°C within 60 seconds, minimizing thermal stress and ensuring dimensional stability. The first stage uses recirculated water (60-70°C) for controlled cooling, while the second stage employs chilled water (15-20°C) for final temperature reduction.

PLC+HMI Interface: A 15-inch touchscreen provides real-time monitoring of insulation thickness (±3% accuracy via laser micrometers), line tension (50-5000 N range), and nitrogen pressure (0.2-0.6 MPa). Supports remote access via industrial Ethernet for process optimization.

Safety Features: Explosion-proof design (ATEX Zone 2 certification) for the curing tube area, automatic nitrogen leak detection with audible/visual alarms, and emergency shutdown within 0.5 seconds of critical parameter deviations.

Power Transmission

Manufactures 110-132kV XLPE cables for long-distance energy transmission networks, with low dielectric loss (≤0.002 at 50Hz) ensuring minimal energy waste. Complies with DNV GL requirements for offshore wind farm inter-array cables, including resistance to salt mist and UV exposure.

Enables production of segregated phase cables for urban substation connections, with precise insulation concentricity (±5% tolerance) to prevent partial discharge.

Industrial Infrastructure

Produces 6-35kV cables for mining and heavy industry, featuring high abrasion resistance (Taber test ≤5 mg loss after 1000 cycles) and flame retardancy (IEC 60332-3-22 Cat. C).

Supports armored cable production with integrated steel tape application, ensuring mechanical protection in harsh environments.

Submarine Cable Systems

Processes armored submarine cables (50-150 mm diameter) with water-blocking layers (longitudinal and radial), tested to IEC 60727 standards for water tightness under 10 bar pressure.

Accommodates lead or aluminum sheathing lines for additional corrosion protection in marine environments.

Renewable Energy

Manufactures cables for solar inverter connections and wind turbine interconnections, with UV resistance (ISO 4892-3:2016 3000-hour exposure) and -40°C low-temperature flexibility (IEC 60811-404 test).

Q: What voltage ranges can this CCV line handle?

A: It supports 6-132kV XLPE cables as standard, with customizable cooling segments and extrusion parameters to accommodate insulation thicknesses from 0.8 mm (6kV) to 12 mm (132kV).

Q: How does the nitrogen consumption compare to traditional systems?

A: The closed-loop nitrogen recovery system recycles 90% of used nitrogen, reducing consumption by 40% (≤5 m³/h) compared to open-loop systems that typically use 8-10 m³/h.

Q: Is it compatible with third-party compound suppliers?

A: Yes, it works seamlessly with all major XLPE brands (e.g., Dowlex?, ExxonMobil Enable?), with material-specific screw profiles available for optimized processing of different compound formulations.

Q: What certifications does this line hold?

A: It complies with CE (Machinery Directive 2006/42/EC), ISO 9001:2015 for quality management, and ISO 14001 for environmental sustainability, with low noise emission (≤85 dB(A)) and energy-efficient components.